Superior Cast Iron Skillets From Marquette Castings

I love cooking with Cast Iron, it’s great in the woods, at home and anywhere else I end up cooking. It’s not the lightest stuff to cart about so I don’t always use it, but when I can, I do.

Every now and then we get a heavy package coming to Outdoor Revival HQ and I’m always hoping it’s some new Cast Iron arriving.

So, Seeing this new Cast Iron cookware on offer from Marquette Castings I thought it would be a good idea to give you a heads up as there’s lots of you that appreciate good cookware just as much as I do.

This is an Indiegogo crowdfunding project that’s already exceeded its goal by 289% so it’s definitely going ahead and yu can still get a good deal purchasing from the Indiegogo page.

Here’s some more information from their page:

Cast iron is one of the best materials ever used for cookware. Its legendary cooking properties, durability, and versatility make cast iron a staple in every kitchen. When Teflon took over the cookware universe in the 1960’s nearly all of the famous manufacturers stopped creating their legendary cookware and closed their factories.

Non-stick coatings breakdown fairly quickly and become useless after the coatings flake off whereas cast iron cookware is routinely used for generations.

With the rise of the new foodie culture, there has been a renewed interest better cooking tools and better cast iron.

We decided to develop our skillets because none of the current manufacturers have created a product that can replicate the quality of the vintage pans. Our goal was to bring back the vintage quality and add some aspects that would make our pans easier to use.

The weight of cast iron is one of the biggest drawbacks to the material. This is why reducing the weight of the cookware was one of our main design goals. Lighter cookware is easier to handle and clean. In order to make cast iron cookware more convenient, we knew it needed to be sold completely seasoned and ready to use, not just lightly coated to prevent rusting like some manufacturers.

This is what drove us to create an industry leading seasoning process, so each pan is ready to use right out of the box. We also designed our cooking surface to hold the seasoning better than any other skillet, so that it requires re-seasoning less often.

Modern foundries are not equipped to achieve the desired wall thickness or surface finish with typical sand casting. Casting in sand and then milling is one way to reduce weight, but it introduces an imperfect secondary process and can’t correct every surface of the pan.

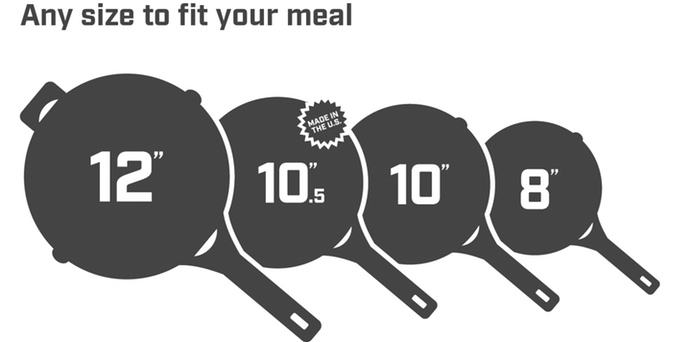

We discovered that by using a process called Investment casting (lost wax) that the wall sections could be thinner and the finished product would be much smoother on ALL surfaces – just like the vintage pans. We use investment casting for our 8″ and 10″ skillets, but due to its size the 12″ is cast in sand molds then milled.

Keeping the pans from rusting after manufacturing is a problem that any cast iron manufacturer needs to address.

One coat of vegetable oil will solve that problem, but makes for a very bad “seasoning”. Also, if not done properly, the “pre-seasoning” oil can lift during use, making for a very poor base for future seasoning. We decided to turn this technical problem into a feature by finishing each pan with 4 coats of baked on flax seed oil.

Our testing and research shows that flax has among the best properties of any seasoning oil option. Since the inside of our skillets are extremely smooth, we found it necessary to use Greg Blonder’s etching recipe to better prepare the surface so that the seasoning oil can stick.

After the skillets are cast they are soaked in a recipe of hydrogen peroxide and sulfuric acid for a short period of time. This etching microscopically erodes the surface grain of the iron, creating a “micro pitting” that provides a much better surface for the oil to adhere. This process results in a pan that is ready to use right out of the box with no further seasoning necessary, it also creates a seasoned base that is more durable and less likely to break down over time.

The skillets are then finished with 4 coats of baked on flax seed oil. The skillets spend about 3 hours in the oven per coat to fully cure the oil. The flax seed oil creates a hard and durable base to build further seasoning upon as your pan ages.

See this page for more information and to purchase your own Marquette Castings: Superior Cast Iron Skillets.

If you have any comments then please drop us a message on our Outdoor Revival facebook page

If you see a good product or have a blog you would like to share let us know about it on our FB page, we’re also happy for article and review submissions , we’d love to hear from you.

Outdoor Revival – Reconnecting us all to the Outdoors